Sewing by hand is a form of art that is over 20,000 years old!! Sewing needles started out as being made from bones or animal horns. The first thread ever used was made from sinew. Needles made from iron were invented in the 14th century and in the 15th century came the eyed needles.

The first person to receive the first British patent for the mechanical device that aided the art of sewing, was a German-born engineer who was working in England, by the name of Charles Fredrick Wiesenthal in 1755.

However, the patent that Charlies received was for the needle that he had designed for the machine. No machine was ever mentioned in the patent or that a machine even existed.

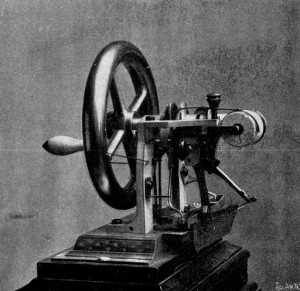

The first patent for a complete sewing machine was recorded 1790 and issued to a cabinet maker and English inventor, Thomas Saint. It is not clear however if Saint was the first to person to build a working prototype of his invention.

The machine described in the patent was an awl that punched a hole in leather or canvas material and it passed a needle through the hole, it also had the overhang arm, a vertical needle bar, a looper and had a feed mechanism (for short leather pieces). Other machines built from this description did not work.

Saint’s machine used the “chain stitch” method, in which it used a single thread to make simple stitches in the material. The “needle” was a stitching awl that had a forked pointed rod that carried the thread through the hole, hook underneath, then moved to the next stitching place, repeat the step and thus lock the stitch.

Saint designed his machine to help the manufactures who produced various leather goods, such as bridles and saddles, but manufactures of canvas goods and ship sails could use the machine as well.

It was the most advanced machine of Saint’s time; however, it would need constant improvements before it would ever be a practical proposition.

Ok, so moving up to 1804, Englishmen James Henderson and Thomas Stone built a sewing machine and obtained a French patent for “a machine that emulated hand sewing” and John Duncan of Scotland, constructed a machine for embroidery that used multiple needles, was granted a patent that same year. Sadly, both machines failed and were soon forgotten.

In 1807, Austrian tailor, Josef Madersperger, began developing his own version of the sewing machine and in 1814 it was presented as a working model.

John Adams Doge and John Knowles invented the first American sewing machine in 1818, however it failed to sew any amount of fabric and then malfunctioned. So it seems that all first attempts at making a usable sewing machine started out kind of rough.

In 1830, Barthelemy Thimonnier, a French sailor, came along and invented the first functional sewing machine. It used only one thread and hooked needle that used the same chain stitch for both regular sewing and embroidery.

Thimonnier had signed a contract with a mining engineer, Auguste Ferrand, who made the requisite drawings and submitted the patent application. It was issued on July 17, 1830. That same year, with partners, opened the first machine based clothing manufacturing company that produced army uniforms for the French Army. Thimonnier was almost killed by a French group of tailors, who were enraged because they feared that his invention would cause them to become unemployed, when they burned down his garment factory.

Walter Hunt invented the first American “lockstitch” and somewhat successful sewing machine in 1832. His invention used an eye-pointed needle (eye & point at same end) that carried the top thread and a falling shuttle that carried the bottom thread. The needle was curved and moved through the fabric horizontally, leaving the loop as it withdrew. As the shuttle passed through the loop, it interlocked the thread. Hunt decided not to pursue a patent, as he thought it might cause unemployment, so the first American patent was in 1842 issued to John Greenough.

Newton and Archibold, two British partners, introduced a machine with the eye-pointed needle and it used two pressing surfaces that kept the fabric in place while sewing, which was in 1841.

However, in 1844, the first machine that used all the disparate parts of past inventions was a modern invention made by an English inventor John Fisher, which was used in the production of lace. It was similarly made like the machines made in the following years by Elias Howe and Isaac Merritt Singer. Unfortunately, due to poor filing of John’s patent at the Patent Office, he didn’t receive the recognition for the modern version of the machine in the legal disputes between the two Americans.

In 1845, a sewing machine was created yet again by a man named Elias Howe, who was born in Spencer, Massachusetts. His machine used a system similar to John Fishers, but there was just one exception, Howe’s machine held the fabric vertically.

He also improved the needle, making it run away from the point, starting at the eye. The needle pushed through the fabric and made a loop on the other side, a shuttle that was on a track then slipped a second thread through the loop, thus creating what we call the lockstitch.

Howe began to encounter problems with people trying to infringe on his patent, including Singer, he struggled for nine years to not only enlist interest in his machine, but to also protect it from imitators.

In 1854, Howe won a case of patent infringement and was granted the right to collect and claim royalties from the various manufactures that used any ideas covered by his patent, which included Singer.

If Walter Hunt had patented his machine, then Howe would have lost the case and Singer would have won, but since Hunt didn’t and Isaac Singer lost, Singer then had to pay Howe patent royalties. And on top of all this and make it somewhat complex, if John Fisher’s patent had not been lost, he would have been in on the sewing machine patent war that was going on, as his machine for making lace looked very much like the machines that Howe and Singer were making.

After Howe was able to defend his rights to the patent and the right to his share of the profits of his invention, Howe saw his yearly income climb from three hundred a year to two hundred thousand dollars a year. Wow, sounds pretty good to me. Between the years 1854 and 1867 he had earned close to two million for his version of the sewing machine. And then during the Civil War, he donated a portion of his earnings to help equip an infantry regiment for the Union army and also served as a private in the regiment.

Even though Isaac Merritt Singer didn’t invent a sewing machine, he did patent the first commercially functional sewing machine, being a trained engineer, Singer did design a sewing machine from seeing a rotary sewing machine that was being repaired. He thought that the machine he saw was clumsy and decided that he could design something better.

He decided that instead of a rotary shuttle, he would use a falling shuttle, the needle would be mounted vertically and he added a pressure foot that held the fabric in place. The arm that held the needle was fixed and had a basic tensioning method. He had combined Howe’s, Hunt’s and Thimonnier’s invention elements. In 1851, he was granted an American patent and given advice that he should patent the pedal foot (treadle as its now called) that he used to power his machine, but it had already been around and used for too long that a patent couldn’t be issued.

Elias Howe heard of Singer’s machine and sued Singer for patent infringement and won the case, so, Singer was then forced to pay Howe a certain sum of money for the machines that were already manufactured. Singer then took out a license under Howe’s patent and paid $1.15 for each machine.

While all this was happening, Allen B. Wilson had developed a shuttle that “vibrated” or reciprocated in a short arc, and by far a better version than that of Howe’s and Singer’s. However, there was a patent already for a similar device patented to John Bradshaw, who threatened to sue. So, Wilson decided to try something new, he partnered up with a man named Nathaniel Wheeler in which to produce a rotary hook in place of the shuttle. Ingenious, right? They thought so.

This change made the machine run quieter and smoother than the other methods used and so, the Wheeler and Wilson Company went on to produce more machines with this new method than any other manufacturer in the 1850’s to the 1860’s. The four-motion feed mechanisms that we see on models today are another one of Wilson’s inventions. This is what creates the forward, down, back, and up motion, which helped pull the fabric through in an even and smooth motion.

Companies began to sue each other more and more through the 1850’s. All this triggered what’s called the Sewing Machine War. So, Singer, Howe, Wilson, Baker, Grover and Wheeler formed something called the Sewing Machine Combination. It was a way that they could combine all their patents, which meant that all other manufacturers had to get a license and pay, for each machine, $15. The last patent expired in 1877, thus ending the Sewing Machine Combination.

Through the following years, more sewing machine manufacturing sewing machines began to appear. I.e. William Jones partnered with Thomas Chadwick, they produced machines from Howe’s and Wilson’s designs under license. Chadwick later teamed up with Bradbury&Co. William Jones went on to open a factory in Guide Bridge, Manchester, in 1869. It was claimed to be the “Largest Factory in England Exclusively Making First Class Sewing Machines” in an 1893 Jones advertising sheet. The firm was later renamed Jones Sewing Machine Co. Ltd, then became Brother Industries of Japan after it was acquired in 1868.

The sewing machine industry continued to increase on through the following years, its evolving and each model from the various manufacturers are constantly being upgraded.

Today, plastic parts instead of metal, thus making the sewing machine lighter in weight. You can even get a machine that you can program, like you would a computer, to embroider a design on any fabric. Everything is changing, technology is improving old methods. And technology will continue to grow. Who knows what the sewing machine will look like in a few years.